Quest employees assemble a Foton Tunland twin-cab at the company's assembly plant in Mutare last week

Quest Motors does not require a capital injection but rather Government support through the purchase of the company's wide range of vehicles.

Quest Motors Manufacturing Engineering Manager Mr Ezekiel Moyo told The Herald Business during a tour of the plant in Mutare last Friday that the company has got the capacity to assemble a wide range of vehicles but there were limitations to how far they could go as sales volumes are subdued.

Mr Moyo, however, said only Government had the capacity to purchase its products through its varied departments.

"We do not need capital injection, what we need is our vehicles to be bought. Individuals cannot afford our vehicles . . . our cheapest a Chery QQ goes for $12 000. If we push volumes, we can buy kits in bulk and this will push down the price of motor vehicles."

Quest assembles Foton Tunland double and single cabs, Chery QQ3, Chery Tiggo, tippers and many other light weight vehicles. The Foton Tunland double-cab costs $42 000, Chery Tiggo $26 000 for manual and $31 000 for automatic.

Mr Moyo said they were in talks with some banks over the provision of credit facilities for the vehicles.

He said the downstream effects of reviving the firms were massive as they directly dealt with over ten local companies.

"We talk of the timber industry where we get wood (wattle charcoal) for manufacturing our own gas, glass industry, tyre manufacturing industry, air filter manufacturers and many other companies will benefit if Quest starts operating not only at 100 percent, but even at 40 percent."

At present, capacity was less 5 percent but there was no set output as this varied per month. Production can get to be as low as six cars per month or 35 per month.

"And that's because the turnover rate is not where we want it to be. It also depends with the model. If it is a tipper, we can do one per two days" At peak the plant could do 35 cars per day.

If it was to run at full capacity, the plant can employ 1 500 people but due to the current crisis the workforce has been shed to 130.

The group currently deals with four Chinese companies in line with the Government thrust of Looking East. The four are JMC, Chery, Foton and more recently Zhong Tong Bus.

Mr Moyo said the group recently signed a Memorandum of Agreement with ZhongTong and assembling of the buses would start soon.

"We had, however, imported complete ones for marketing purposes."

Mr Moyo said these were the best brands. The company used to assemble Land-Rovers, Peugeot and Nissans. "The Foton Tunland won the best bakkie of 2013, Chery Tiggo won an award in 2011.

"We can't say we want to assemble the Mazda model but there is marketing department which does the research on the best brands suited to the country."

The group is also providing related services, such as wheel alignment, spray painting and basic service through their service centres.

Quest was the first assembling plant to be built in the country. It was built in 1958 while the first car was produced in 1960.

- The Herald

Concern over Masvingo black market

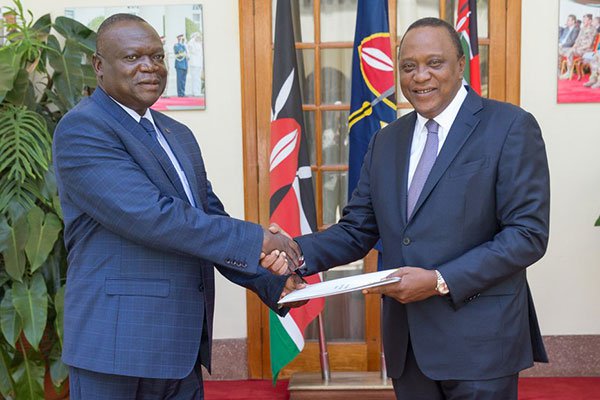

Concern over Masvingo black market  Kenya declares three days of mourning for Mugabe

Kenya declares three days of mourning for Mugabe  UK's Boris Johnson quits over Brexit stretegy

UK's Boris Johnson quits over Brexit stretegy  SecZim licences VFEX

SecZim licences VFEX  Zimbabwe abandons debt relief initiative

Zimbabwe abandons debt relief initiative  European Investment Bank warms up to Zimbabwe

European Investment Bank warms up to Zimbabwe  Young Investment Professional (YIP) Graduate Programme 2019

Young Investment Professional (YIP) Graduate Programme 2019

Young Investment Professional (YIP) Graduate Programme 2019

Young Investment Professional (YIP) Graduate Programme 2019

Editor's Pick